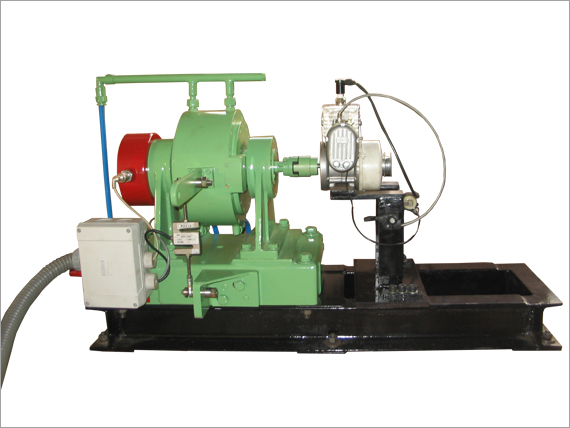

We are Manufacturer, Supplier, Exporter of Kolhapur of Eddy Current Dynamometers from Kolhapur, Maharashtra, India.

We are one of the well known manufacture and supplier of derives assortments of various supreme quality Industrial Dynamometers. Our products are widely used in various automobile industries to cater the requirement of two wheeler, three wheeler and four wheeler as well as Gear-Box, Electric Motor, and transmission Manufacture Industries.

- Capacities from kW up to 720 kW available

- Low Inertia Rotors

- Fast Response

- Single Rotor and Multi - Rotor machines can be manufactured

- Dynamometers are designed for Universal Application in all Types of Testing like for Engines, Turbines, Motors, Components and PTO testing.

- All Type Eddy Current Dynamometers can be connected to both open as well as closed cooling water circuits

- Calibration systems with levers & weights allow simple & precise adjustment and checking of the torque measuring chain, regardless of whether the brake is at standstill or rotating.

- Multi-rotor Construction Dynos available for High Performance and High Speed Petron Engine Testing

- Extremely Reliable Machines to ensure long life with performance & accuracy

- Universal range of application for examinations on engines and engine assemblies

- Development of Petrol & Diesel engines for cars and commercial vehicles

- Development and testing of engine assemblies, e.g. Pistons, Ignition systems, Sealing, Filters, Carburetor and Fuel Injection equipment, Exhaust gas ducting and catalysts

- Quality Control

- Development and Testing of Fuels and Lubricants

- Low moment of inertia due to disc rotor construction

- High torque within low range of speed ; low torque when idling

- Exceptional control characteristics when used with ATEE's control unit and power unit

- Euro 3 (Load Response Test) and US - Smoke Test compatible

- High measurement accuracy

The principle of the eddy current dynamometer is based on a simple interaction. As soon as current flows through the excitation coil, a magnetic current is formed whose flux lines close around the coil. If the rotor is moved within this field, eddy currents are induced in the sides of the cooling chamber. These eddy currents construct a counter-magnetic field which then brake the rotor. The influx of mechanical energy is thereby transformed into heat and led off by the water.