- For Testing Power Take Offs (PTO) of Machines like Agricultural Tractors, Power Tillers. Agricultural Implements like Rootavator etc.

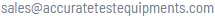

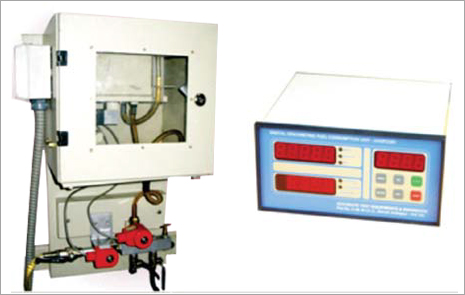

- Coupled to Eddy Current Dynamometers

- Complete System Can be provided including Dyno Lifter, Cardan Shaft, Fuel Meter, Weather Station and Computerized Data Acquisition and Control Can be Provided

- PTO Dynamometers are used for testing Power Take Offs of Tractor, Power Tillers and of Various Agricultural Machinery

- E-400, E-500 and E-720 Dynamometers are used as Loading Unit in PTO Dynamometers

- Electro-mechanical and Hydraulic Lifts options available for Dyno Lifter for aligning Dyno Shaft Centre with that of Tractor Under Test

We are Manufacturer, Supplier, Exporter of PTO (Power Takeoff) Test Systems from Kolhapur, Maharashtra, India.

| Model | Max Torque (N-m) | Max Power (Kw) |

| E-400 | 2000 | 400 |

| 650 to 1910 | 1910 to 5000 | |

| E-500 | 3000 |

500 |

| 500 to 1590 | 1590 to 4500 | |

| E-720 | 4500 | 720 |

| 400 to 1528 | 1528 to 3750 |

Applications :

- PTO Dynamometers are used for testing Power Take Offs of Tractor, Power Tillers and of Various Agricultural Machinery

- The Application Software is Customized as per various Test Codes applicable in various regions across the world

Advantage :

- Turnkey Solution gives a reliable equipment to be installed within minimum time frame.

- Customisation in test codes and in report generation is implemented as per requirement.

- Reliable Eddy Current Dynamometer Loading Unit and Digital Control Ensure very close control of Load during testing

Principle :

The principle of the eddy - current dynamometer is based on a simple interaction as soon as current flows through the excitation coil, a magnetic current is formed whose flux lines close around the coil. If the rotor is moved within this field, eddy currents are induced in the sides of the cooling chamber. These eddy currents construct a counter - magnetic field which then brake the rotor. The influx of mechanical energy is thereby transformed into heat and led off by the water.